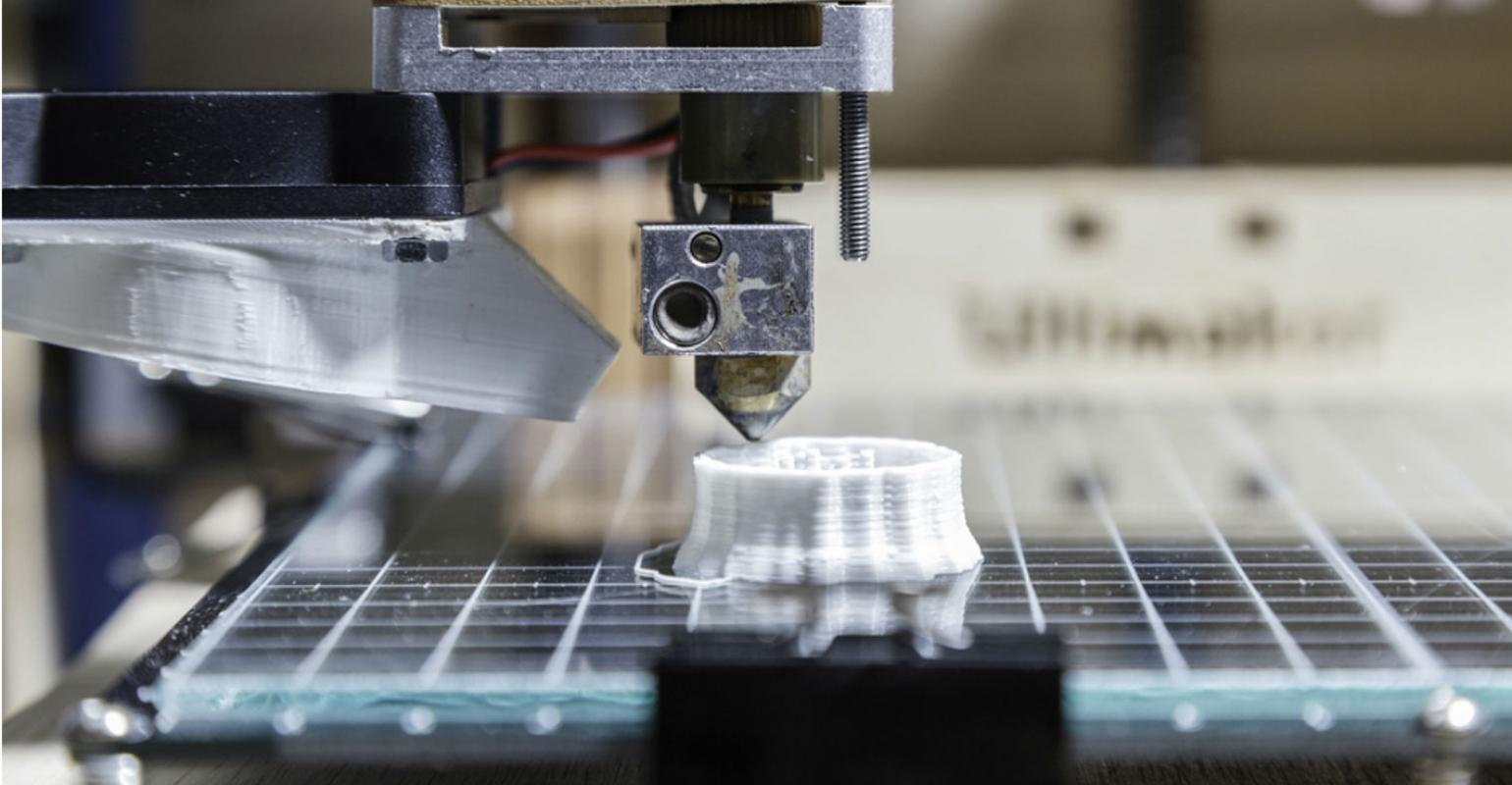

Additive manufacturing is a process of making three dimensional solid objects from a digital file. Unlike printing a flat picture for example on a piece of paper, a 3D printer actually builds something in 3 dimensions. So to call it printing is a bit misleading. The device builds upward and outward with each progressive layer of material. The creation of a 3D printed object is achieved using additive processes. In an additive process, an object is created by laying down successive layers of material until the object is created in three dimensions. Each of these layers can be seen as a thinly sliced horizontal cross-section of the eventual object. 3D printing enables you to produce complex, functional, shapes using less material than traditional manufacturing methods. The number of production-ready additive manufacturing platforms that ship each year will increase more than 10 times by 2030, as the technology’s use in structural and mission-critical commercial applications comes to fruition.

According to a new report published by ABI Research, a market-foresight advisory firm, these systems will produce more than $360 billion worth of parts and end products each year and nearly $2 trillion in sum by the end of the next decade.

Markets For Additive Manufacturing

There is so much fascinating technology around us today. Everyone wants to believe the next one will be a game changer. The major interest in this particular technology is the potential of additive manufacturing to do much of a company's own manufacturing rather than engaging in trade to buy products from other sources. 3D printers capable of creating just about anything in color and multiple materials already exist and will continue to improve to a point where functional products will be able to be created. The automotive industry represents the largest opportunity globally with $148 billion in additive manufacturing product value forecast for 2030, but it is closely followed by the machinery markets, and these figures differ from country to country. The United States currently leads the world in terms of AM product value but will be passed by China in 2029 under present conditions. Additive manufacturing brings production closer to the places where products are sold and used. For suppliers, this means the ability to better dictate the priority, timeliness, and process that best fits their manufacturing needs. 3D printing has the potential to change the manufacturing world as we know it.

Additive Manufacturing Will Likely Affect The Global Supply Chain

This technology has the potential of transforming our global supply chain in a very profound way. How profoundly, at this point, is very unclear. Any supply chain begins with a manufacturing point. Then warehousing, inventory management and, of course, transportation arrangements. Now AM technology allows us to reduce manufacturing lead times, as well as transportation costs, and also reduce the carbon footprint associated with production and distribution. AM shouldn’t be thought of purely for manufacturing since it could have much broader supply chain implications. The original applications were originally used for printing small numbers of simple objects made of one or two materials but that's rapidly changing. Its most promising initial contribution may come in a couple of basic areas.

Manufacturing Customization

Though mass customization, creating products that fit perfectly with the desires of one customer, is a very hot topic and trend, all of these elements represent a cost and quite an effort. This means you need to make sure it is right for your application and industry, and that the added value for your customer matches your effort. Manufacturing lead times and transportation cost savings can be erased quickly with inaccurate customer data requirements. Simple examples of this mass customization may be common consumer products like earphone buds, cell phone cases or sunglasses.

Spare Or Replacement Parts Market

Another significant advantage to 3-D printing is the replacement or spare parts industry. When the Maytag man, or whomever, shows up to repair your home appliance there is no need for inventory in his truck. Just a 3-D printer and some software. The same argument can be made for just about any similar service type industry.

What's Ahead

AM technology still has some obstacles to deal with. There are implications for the digital supply chain to go along with the physical one since the intellectual property resides in the file from which the object is printed rather than the product itself. Therefore security will be an issue in handling and shipping these types of assets.

This means that in the future, we’ll need to really examine this data chain to ensure that the information it contains is securely transported and managed. This is where technology like blockchain would likely be useful. This is a great growth opportunity for the global logistics supply chain industry. This is also where the digital supply chain technology comes in. To stay current on these technologies and more, subscribe to our blog www.Land-Link.com.

Land-Link, a well respected professional organization, has been providing its clients with effective transportation and logistics solutions since 1978.

Land-Link, a well respected professional organization, has been providing its clients with effective transportation and logistics solutions since 1978.