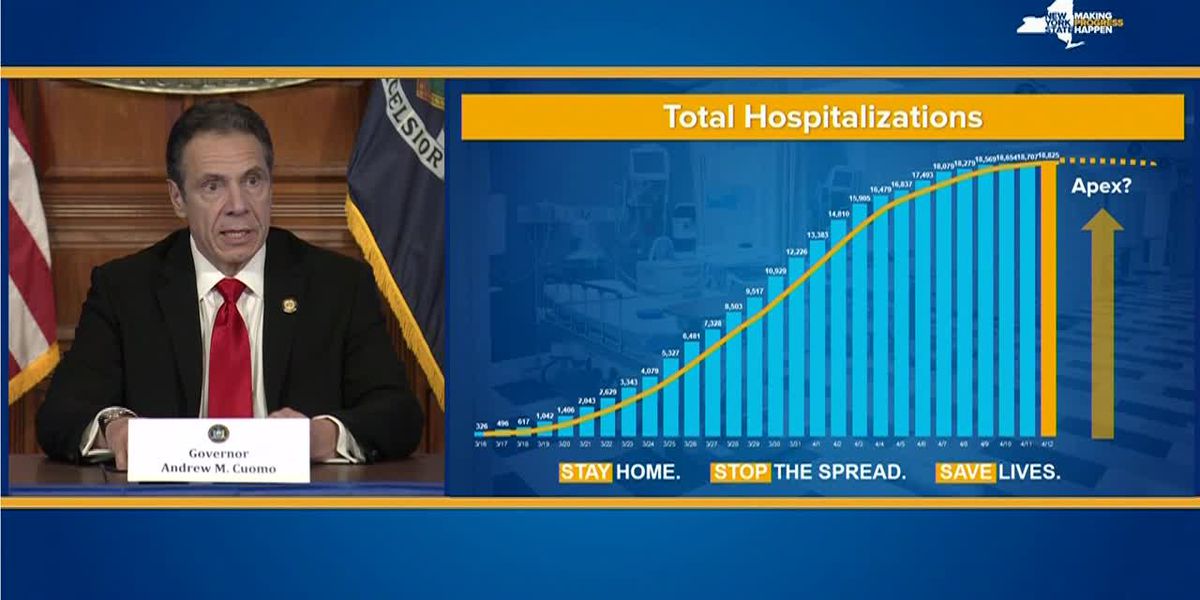

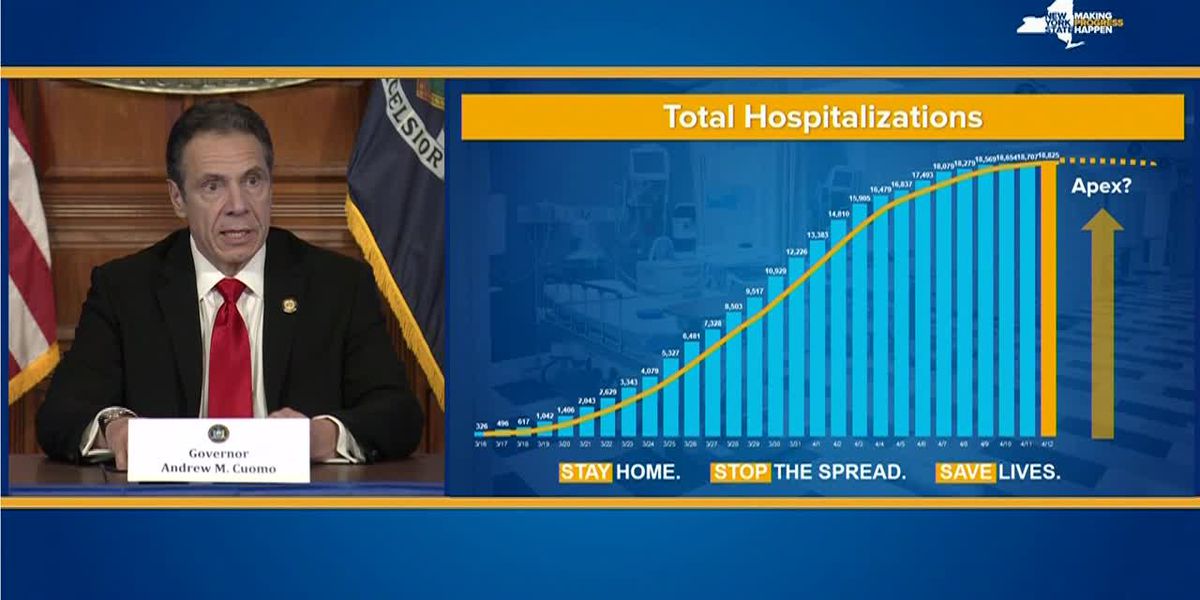

Many states have reported a leveling-off of new Covid-19 cases. Clearly a good sign but we are by no means out of the woods yet. It is unlikely anyone alive today remembers the Spanish flu of 1918, but we may be able to learn some things to expect as we hope to return to some normalcy in the coming months. The administration is already talking about target dates to reopen the country in stages. The fallout from Covid -19 is painfully clear for many people. Let’s try to anticipate what challenges are ahead.

From a logistics and supply chain perspective, while things are still very early, it stands to reason that the impact on all things trade, shipping, and moving freight is already quite significant. There is also, of course, a high level of uncertainty that comes with a pandemic such as this one, in the form of how long it may last for, what should or could businesses be doing to get through this period, and what happens now or next? And what they all have in common is that they are all valid questions that come with a shortage of valid answers, at least so far, for the most part. The impact on supply chains more broadly will be a function of (a) how long businesses remain closed (b) the extent to which there’s an impact on downstream supply chains and (c) the extent to which precautionary measures are taken by corporations including logistics firms. We may be able to glean some information on what to expect during the recovery period by looking at the post Spanish flu recovery.

What Can We Learn From the Spanish Flu Recovery

The immediate effects of the pandemic; postponed weddings, canceled vacations, empty supermarket shelves, sinking housing prices, salary cuts, and layoffs suggest no one will come out of this period without losing something but we are only at the beginning. Predicting how bad things will get economically is difficult. A viral outbreak of this scale has only happened once before in the industrialized world: the 1918 influenza pandemic that hit the world in two seasonal waves, killing 50 million people worldwide and 675,000 in the US. That pandemic occurred during World War I, which makes it hard to compare to now, even setting aside all the other changes in the past century but we may be able to draw some loose parallels.

Many businesses, especially those in the service and entertainment industries, suffered double-digit losses in revenue. Society as a whole recovered from the 1918 influenza quickly, but individuals who were affected by the influenza had their lives changed forever. Given our highly mobile and connected society, any future influenza pandemic is likely to be more severe in its reach, and perhaps in its virulence.

Two months into this current outbreak, massive layoffs have started, American industries have demanded bailouts, and unemployment rates have surged. Economists at the Federal Reserve Bank of St. Louis are projecting total employment reductions of 47 million — an unemployment rate of 32.1%.

According to Forbes, every sector of the American economy is shrinking: Hotel chain Marriott International is furloughing tens of thousands of workers, Landry’s, the parent company of Del Frisco’s and Bubba Gump Shrimp, laid off 40,000 workers. Air Canada plans to lay off 5,100 members of its cabin crew. Shoe retailer DSW put 80% of its workers on a temporary unpaid leave of absence. This early carnage is understandable. How fast we recover will make all the difference to the U.S. economy. Is this perhaps a wakeup call for domestic industry revitalization? There is a strong call to bring back the industrial revolution but are we too late?

What’s Ahead is Uncertain

As we look ahead, more information about corona virus will be learned about, to be sure, but things understandably are moving slowly. Freight transportation activity, processes and volumes are likely to be impacted to varying degrees, of course. For now, we assess and move forward as best as possible. Events like this on a global level can make for trying and difficult times, but, as has been the case before, one can expect supply chain networks to adapt and adjust and do what needs to be done to keep economies and freight flows moving forward. Land Link Traffic Systems is available for your supply chain needs.

Read More

Land-Link, a well respected professional organization, has been providing its clients with effective transportation and logistics solutions since 1978.

Land-Link, a well respected professional organization, has been providing its clients with effective transportation and logistics solutions since 1978.