.jpg)

A new generation of shopping options through e-Commerce and m-Commerce (mobile commerce) has made supply chain management a vital area of concern for many businesses. It is particularly critical for manufacturing companies, which are heavily dependent on the supply chain partners to deliver their products. With an increasing emphasis on technological advancements, as well as the changes in customer expectations, the need for integrated supply management has become increasingly important. In the retail environment particularly, where the margins are thin, technology is the key component between profit and loss. And in this market, the sharks are circling.

Wal-Mart Is Making Hi-Tech Moves

This July, a Walmart supply chain first is coming to Colton, California. A newly built, 340,000-square-foot high-tech consolidation center will be the first in Walmart’s supply chain to receive, sort and ship freight. This automated technology will enable three times more volume to flow throughout the center and helps Walmart deliver the right product to the right store, so customers can find the products they need.

Amazon Started This Fight

Back in 2005, Amazon launched its Amazon Prime service. Customers, paying an annual membership fee, received guaranteed two-day shipping on hundreds of thousands of products. In fact, the introduction of two-day delivery was the game changer and established the dominance of Amazon in the online retail industry. When many other retailers started to catch up with that strategy by offering their own free two-day shipping, Amazon tipped the playing surface by offering a one-hour delivery with its Amazon Prime Now service. The fight now seems who can deliver product faster. The rub, however, is it has to be done at a profit.

The Latest Wal-Mart Approach

A massive Walmart-owned center, which will open in July with 150 full-time associates, can move three times as many cases. It will grow to employ more than 600 associates by 2021. With the combined might of people and world-class logistic technology, this facility will be the most efficient consolidation center in Walmart’s supply chain. Walmart continues to expand its portfolio of high-tech distribution centers. In October, Walmart announced that it had broken ground on a tech-enabled perishable grocery distribution center in Shafter, California.

Amazon Sets The Pace

I have to recuse myself of my opinion to some degree since Philadelphia was in the running for an Amazon Distribution Center Headquarters. Sadly, we didn't make the cut. There is one thing I have to admire about Amazon. Management may have adopted the Bill Bellecheck game plan of logistics protocol. They seem to have designed the playbook of online retail from order to fulfillment to the final mile. When Amazon made its official selection for the locations of its second headquarters, it was hardly a surprise to anyone following the lengthy HQ2 saga. But tucked into the announcement were tidbits we didn’t know, including information on what it took for the two sites to win out over the dozens of other bids.

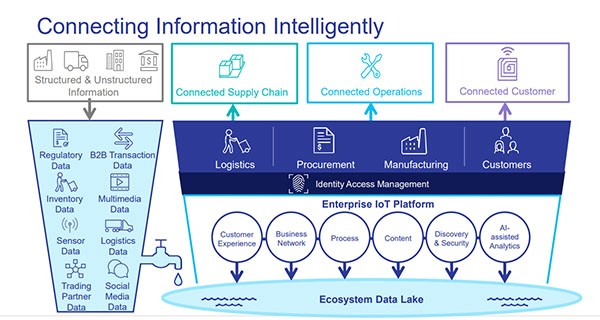

How To Keep Up With The Competition

Target is lagging a distant third in the giant race for a retail giant of the world. The only strategy for small to mid-size retailers to break into this market is to be lean. Operational efficiencies will be crucial for anyone to be competitive. To keep up with your competition subscribe to our blog, or better yet, join the Land-Link.com client family and let us show you what a lean supply chain looks like.

Read More

.jpg)

.jpg)

.jpg)

Land-Link, a well respected professional organization, has been providing its clients with effective transportation and logistics solutions since 1978.

Land-Link, a well respected professional organization, has been providing its clients with effective transportation and logistics solutions since 1978.