As the logistics industry, and the broader business world, looks to 2019, it’s time to explore what the next year will bring to logistics. After reviewing several industry sources most Logistics professionals are in agreement with all of these trends. We hope this information will help your organization prepare for what's ahead.

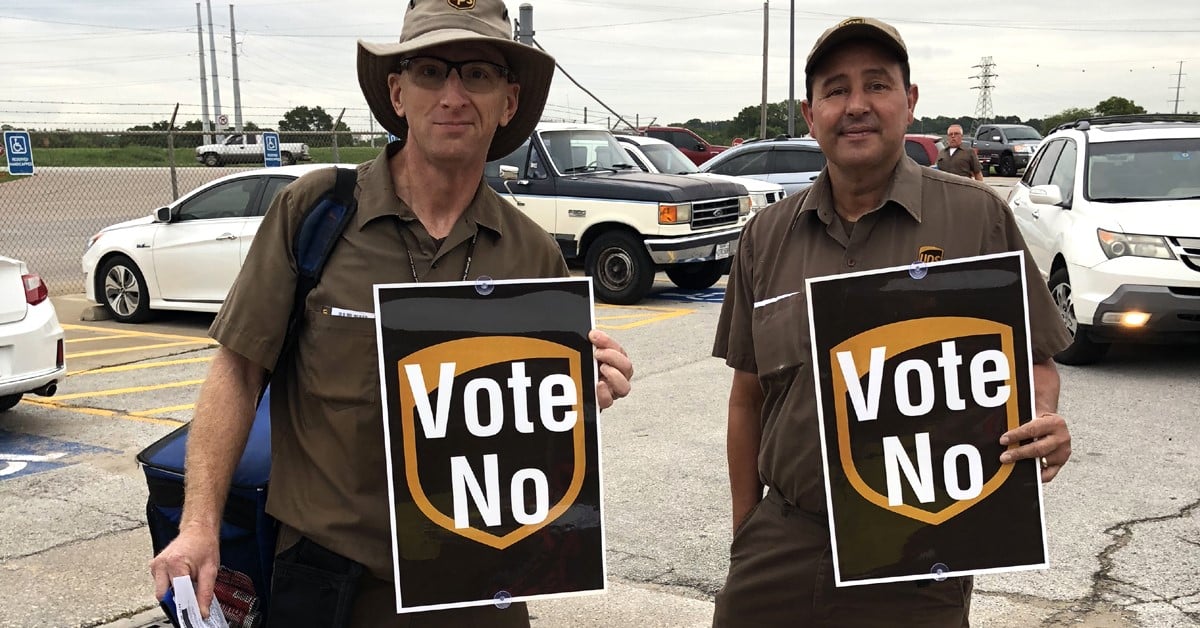

1. The Truck Driver Shortage Will Expand With No End In Sight.

The driver shortage has been an ongoing problem for many years. Among the biggest issue is that there is very little interest in trucking careers for young men and women from the 18 - 28-year-old generation. As of now, it appears unlikely that this truck driver shortage will end soon. World Bank data shows that U.S. import and export traffic nearly doubled between 2000 and 2016. During that time period, twenty-foot equivalent unit (TEU) traffic increased from 28.3 million TEUs in 2000 to over 50 million TEUs in 2016. Despite a huge rise in demand for truckers to transport these imports and exports, the number of qualified drivers is not growing. Young immigrant driver prospects and driver-less technology is simply not enough to fill the void of capable driver solutions.

Driverless trucks probably won’t be here for a few years, mostly due to legal concerns. The good news is once this transition happens, driverless trucks will reduce trucking costs and minimize demand-related trucking shortages.

2. Big Data And Blockchain Technology Will Revolutionize Logistics.

Demand for information technology (IT) services in the logistics industry appears to have increased in recent years as more companies begin to deploy IT resources in their logistics/supply chain operations. That trend will likely continue in 2019 as small and midsize importers and exporters even the playing field against larger counterparts by leveraging big data and blockchain technology.

The implementation of big data will lead to safer supply chains globally. Small to midsize importers and exporters stand to gain the most from new technology since they do not have the resources to create a safe supply chain but will be able to rely on freight companies that provide big data capabilities to customers. The supply chain will be safer, as importers and exporters will have the ability to communicate quickly with global suppliers and automate tasks to minimize human error and eliminate paper.

In 2019, many small to midsize importers and exporters that are working with freight companies will choose to use big data when shipping goods globally. With the touch of a button, they will approve shipment specifications, see their cargo be loaded/unloaded, view the condition of their cargo, read the temperature inside a container, and track important milestones like customs clearance, arrival dates, and delivery receipts. The mass adoption of big data will be a game-changer in logistics.

Blockchain technology will increase transparency for importers and exporters in 2019. It will replace needing extra time and personnel to record transactions within the supply chain. When shipping globally, there are many parties involved, so it will benefit shippers to minimize information disruption, reduce paperwork needed, and maintain access to original information without worrying about tampering during and after shipment.

3. Payments Will Be Safer, And Cross-Border Transactions Will Be Easier.

In 2019, new payment technology will reach the logistics industry on a widespread scale, leading to more secure transactions globally.

The global trend of the last decade toward widespread credit and debit card use, as well as the introduction of cryptocurrency as an alternative form of payment, will accelerate in logistics. In 2019, most shippers will choose to pay for the shipment of goods with major credit or debit cards, as freight companies and other intermediaries are pressured to offer this payment convenience.

This will help everyone, as small to midsize importers and exporters will have payment flexibility, while freight companies can get paid faster.

Globally, the introduction of cryptocurrencies such as bitcoin will become widely accepted, leading to safer payments with an eye toward maintaining customer privacy. Whether a major financial institution introduces its own cryptocurrency remains to be seen, but logistics will be ready. For the logistics industry, cryptocurrency will make it easier for cross-border, international payments to be done safely and privately.

One downside of cryptocurrency is concern over countries being able to side-step economic sanctions by using cryptocurrency to pay for goods. Cryptocurrency pioneers and the banking industry are working on security protocols to address these concerns from international governments...mostly the United States.

4. The Logistics Industry Will Continue To Consolidate, Leaving Few Major Players.

Between 2016 and 2018, major developments in logistics led to the consolidation of major shipping companies. The result is fewer shipping carrier options for shippers.

In 2019, this consolidation will continue, with major players in the shipping industry already numbering less than 10. It has become difficult to survive as an independent shipper with a fleet of cargo ships. To compete, shipping companies have joined forces to form shipping alliances.

Today, the top three shipping alliances are 2M, Ocean Alliance and THE Alliance. Together, they are composed of 11 shipping lines, including most major shipping players. In 2019, more alliances may be formed, shipping lines may move to start new alliances or two alliances may merge. Similar trends are emerging in the domestic logistics environment as well.

By the end of 2019, further consolidation may mean higher rates due to less competition. However, through consolidation, shipping companies will offer top-tier customer service and increased capacity. In 2019, consolidation will continue to be a double-edged sword. For these reasons it is important to develop a relationship with a 3rd party Logistics provider to take advantage of established, volume rates and relationships in order to make your organization relevant at the bargaining table. Contact us at www.Land-Link.com today for a no-obligation consultation.

No matter what happens in 2019, it’s clear that change is coming to logistics. Importers and exporters, as well as domestics shippers, must be prepared for the future Logistics environment, or they will be caught off guard.

Author

Michael Gaughan

Technology Officer

Land Link Traffic Systems

Free Assessment, call 732-899-4242

.png)

.jpg)

Land-Link, a well respected professional organization, has been providing its clients with effective transportation and logistics solutions since 1978.

Land-Link, a well respected professional organization, has been providing its clients with effective transportation and logistics solutions since 1978.